Manure grinder is a machine for crushing manure materials into powders. It is often be used in organic manure fertilizer production line. There are 3 types of manure grinding machines in Shunxin for your reference. Whether you use it for crushing manure materials or pellets, we can meet your needs. For making it serve you well, we use advanced design and special materials when manufacturing. Meanwhile, we can also provide suggestions for you to choose suitable powder processing equipment.

Why should you buy fine powder grinder for your fertilizer production line?

A manure pulverizer is mainly used in organic fertilizer manufacturing line. It is applicable for you to use it after the fermentation. Moreover, you can also use it for crushing the unqualified manure pellets after screening.

Crushing fermented organic manure

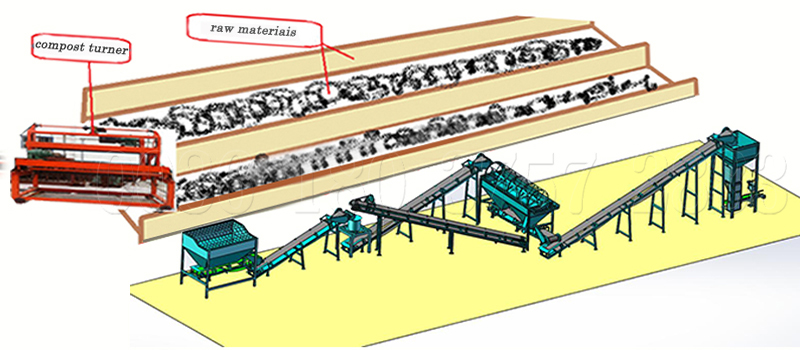

Whether you want to make organic manure powder fertilizer or fertilizer granular, it is necessary for you to crush the fermented organic manure materials. After the compost making process, the manure may be powders mostly. However, there are still some agglomerations. Then it is time for you to use Shunxin manure grinding machine. Generally, semi-wet manure materials grinding equipment and new vertical manure crusher are applicable for crushing fermented organic manure.

After you grind organic manure into fine powders, equipping with a manure mixer can mix powders evenly. And then you can enter the granulating process.

Crushing unqualified manure pellets

After the granulating, drying, cooling and screening, you can get qualified and unqualified organic manure pellets. And then, there is a coating machine for you to process your qualified manure fertilizer pellets. While, how to deal with the unqualified granules? Shunxin provides you chain type manure pulverizer for re-crush pellets into powders so that you can re-granulate.

Manure grinder for sale

Model: SXFLF-600

Power: 22kw

Capacity: 3-5t/h

Size of Feed Port: 400*400mm

Overall Size: 1300*750*1900mm

How to choose an appropriate manure grinder to make powder for your commercial powdery manure making?

Making manure into powder, Shunxin manufactures 3 types of manure grinding machine for your requirements. These 3 machines can make your manure materials into fine powders. It is alternative for you to granulate the organic manure powder or pack them for selling directly.

Semi-wet manure compost grinder equipment for small scale crushing requirements

This machine is a new designed single rotor crusher with high efficiency. It is suitable for you to use the wet manure materials for crushing. The moisture content between 20%-40% is applicable. Using this machine for making powders, the pulverized powder can meet granulating requirements. For your small scale organic manure compost grinding, this machine is the best compost grinder. It will not take you too much space. Meanwhile, the production capacity is suitable.

Besides, Shunxin also manufactures double rotors semi-wet manure powder making machine. This design can help you crush your manure twice for making your manure materials into finer powders.

Semi-wet manure grinding machine for sale

Model: SXSF-40

Capacity: 1-1.5t/h

Power: 22kw

Comminution Size: 50 mesh

Overall Size: 1200*1350*900mm

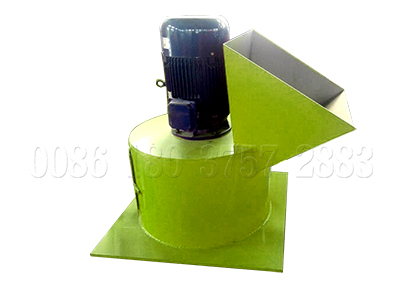

Hot sale vertical chicken waste grinding machine

There is no screen inside Shunxin vertical manure pulverizing machine. While, the fineness of powder is adjustable. It is suitable for you to use it for pulverizing pellets, tablets and so on. This machine is a key equipment in organic fertilizer manufacturing process. Whether you want to make powdery organic manure fertilizer or fertilizer granules, this machine is helpful. What’s more, for your convenient maintenance, there is an inspection window on crusher body. It takes you little time on fixing it. For your middle size organic manure fertilizer powder making requirements, it is available for you to use this machine.

New vertical manure pulverizing equipment for sale

Model: SXFLF-600

Power: 22kw

Capacity: 3-5t/h

Size of Feed Port: 400*400mm

Overall Size: 1300*750*1900mm

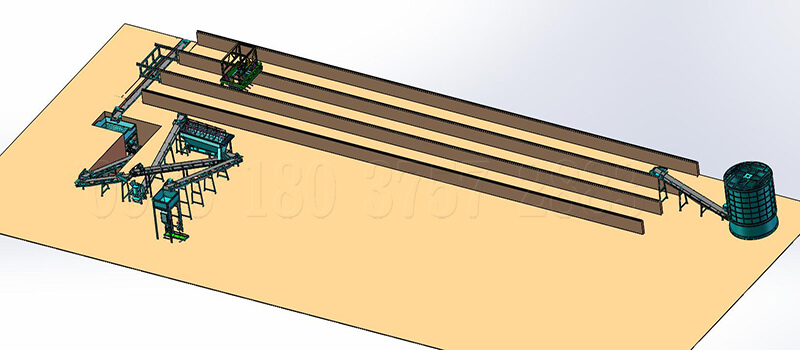

Chain type cow dung powder making machine for re-crushing the manure compost fertilizer granules

Similar to the semi-wet crusher, this chain type pulverizer also has single rotor and double rotors type. The vertical chain crusher is single rotor. While, the horizontal type has double rotors. While, different from the semi-wet and new vertical crusher, this chain type crushing machine is often be used for re-crushing the unqualified organic manure fertilizer granules. Generally, it is popular in the manure fertilizer pellets manufacturing line. You can use it after the screening machine. The fertilizer screener equipment can select the unqualified fertilizer granules out. And then it is applicable for you to send these bigger granules into chain manure pellets grinding machine directly.

After the crushing, you will get fine powder again. The pulveirzed manure granules can be granulate again.

Chain type manure powder making machine for sale

Model: SXLTF-500

Power: 11kw

Capacity: 1-3t/h

Size of Material: < 100mm

Diacharge size: ≤3mm

Top 7 design highlights on Shunxin manure grinder for large yields powdery manure fertilizer production?

- Double rotors chain crusher has high efficiency and production capacity.

- All the manure crushing equipment employ special materials for avoiding sticking.

- Both semi-wet manure pulverizer and new vertical crusher can accept high-moisture materials.

- The double rotors manure crushing machine pulverizes organic materials twice, making sure fineness of powders.

- There is a screen inside semi-wet manure materials grinder. Thus, the wet manure will not block machine and even affect your fertilizer production.

- It is applicable for you to adjust the fineness of manure powders you want.

- The chain crusher can not only crush unqualified organic manure fertilizer granules, but also be suitable for making compound fertilizer materials into powders.

How does semi-wet manure fertilizer crushing machine pulverize?

Other associated manure treatment facilities you may also need to turn powder manure into commercial fertilizer in Shunxin

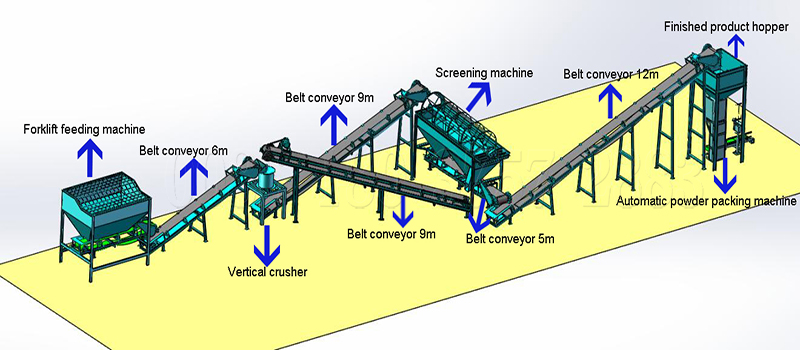

For your organic manure disposal, making the manure waste into organic fertilizer powder is economical and even can bring you much profits. Making fine organic manure fertilizer powder, what you need is not only a commercial compost grinder. There are screening machine and bag filling machine for you to process the organic fertilizer powder for your commercial use. With these two machines, you can get high-quality organic fertilizer powders for selling efficiently.

Qualified and unqualified powder selecting machine

After the crushing, you can get fine powders. And for your commercial purpose, it will be better for you to check the fineness again for better quality. A rotary screen equipment will be helpful for you to separate the unqualified powders, which is too big from the qualified products. Then you can pulverize the unqualified big powders again. Finally, the final products you get will be finer.

Rotary drum manure powder screening machine For sale

Model: SXGS-1020(can be customized)

Power(kw): 3

Reducer Model: ZQ250

Drum Speed(r/min): 21

Capacity(t/h): 1-2

Powdery fertilizer packing machine

Comparing with the pellet making process, you do not need to granulate, dry and cool. It is applicable for you to pack the screened manure fertilizer powder directly. Using Shunxin powder packing equipment can pack your powdery manure fertilizers efficiently and accurately. What’s more, you do not need to worry about the blocking of powders. Because there is a belt inside the machine for avoiding it. Meanwhile, there are many specifications for you to choose according to your production capacity.

Powdery manure fertilizer packing machine for sale

Model: SXH-B10

Function: packing and weighing materials

Weight: 400kg

Voltage: 380v

Packing Speed: 3-4 bags/min

Degree of Automation: fully automatic

When could you use the manure grinder for your organic fertilizer making line?

In the organic manure fertilizer making line, the manure powder grinding equipment is key. Whether for your organic manure powder or granules making requirements, this machine is necessary. For your commercial powdery organic manure compost manufacturing, the manure pulverizing machine can help you make fine powders. And in your organic manure fertilizers granules making line, you had better use this fertilizer crushing machine for granulating better.

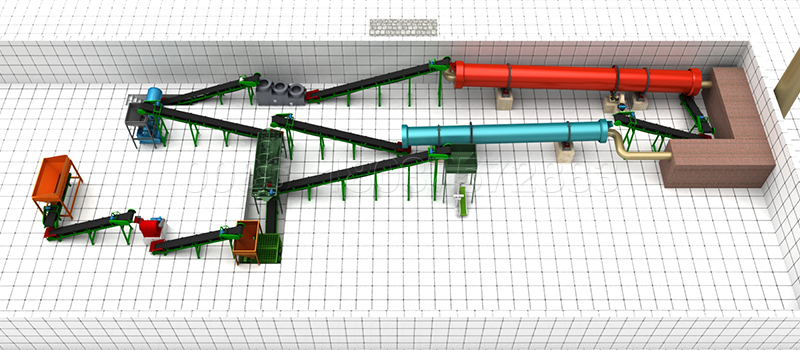

After the manure composting process for cmmercial fertilizer powder making

Generally, after the composting, the manure composts will be suitable for fertilizing. While, for selling organic fertilizers, it is a good choice for you to equip with a commercial compost grinder for making fine fertilizer powder. The semi-wet manure materials crushing mahcine and new vertical organic manure compost pulverizers are suitable for you. They can turn the manure compost fertilizer into highq quality fine powder. And then you can screen and re-crush the unpowdered organic composts.Finally, you can get well pulverized manure fertilizer powder for packing.

Before manure compost fertilizer granulating process for organic manure granulation preparation

Making organic manure fertilizer granules, granulating is an important process for organic manrue granules manufacturing. The manure granulation equipment can only process the powdery materials into granular fertilizers. Thus, you should turn the animal manure composts into powders firstly and then send them into granulating equipment. The finer the manure compost powder, the better the granulating effects. Our granulation machine will pelletize the well crushed fine powder into high quality organic compost fertilizer granules.

How to make your crusher machine work long in your powdery manure processing line?

For making your manure grinding machine works for a long time, Shunxin uses high-quality materials when manufacturing. However, reasonable operation and maintenance are important, too. Then, how should you do to prolong machines service lifetime?

Notice for your operation

- Check whether the circuit is connecting or not. Meanwhile, make sure the parts are tight.

- Do not start machine with load. You had better feed manure materials after you start machine. Or it will block the machine.

- Close power supply when there is no material inside machine.

- Do not put hands or some other things into machine or belts. Or it will break machine and even hurt you.

Tips for your maintenance

- Lubricate bearings before you use it. And change lubricating oil regularly.

- Add lubricating oil on reduction gear. For your information, you had better change oil after working for 100 hours.

- Change lubricating oil every 4 months.

Shunxin manure grinder fertilizer machinery company, a trustworthy fertilizer equipment manufacturer

If you are looking for a manure grinder for making your manure into fine powders, Shunxin is a trustworthy fertilizer equipment manufacturer. We have been manufacturing fertilizer equipment for many years. And our products have good reputations among our customers. What’s more, we can provide you not only manure grinding machine, but also organic manure fertilizer production line. Whether you want to buy a set of organic fertilizer machines or single machine, Shunxin can meet your different requirements. We can provide you professional suggestions for your production requirements. Especially, we can customize for you, manufacturing fertilizer machines for your own requirements. Especially, we have our own factory for manufacturing fertilizer equipment. From materials to designs, we try our best for satisfying you.